The performance of the inductor core is easily affected in a high-temperature environment, so it is crucial to take effective countermeasures.

1. Select high-temperature resistant materials

Material properties are the key. For example, manganese zinc ferrite in ferrite core has good temperature stability and high Curie temperature. Within a certain high temperature range, the performance fluctuations of magnetic permeability and other properties are small. There are also cores made of ceramic materials, which have good thermal stability and low thermal conductivity. They can maintain structural stability at high temperatures and reduce performance degradation caused by temperature changes.

2. Optimize the design of the magnetic core structure

A reasonable structure helps to deal with high temperatures. Use a core shape with good heat dissipation performance, such as a flat core, to increase the contact area with the air and facilitate heat dissipation. When designing the winding, select high-temperature resistant insulation materials and increase the thickness of the insulation layer to prevent short circuit failure caused by the decline of insulation performance at high temperatures. At the same time, optimize the winding layout to reduce heat accumulation between windings.

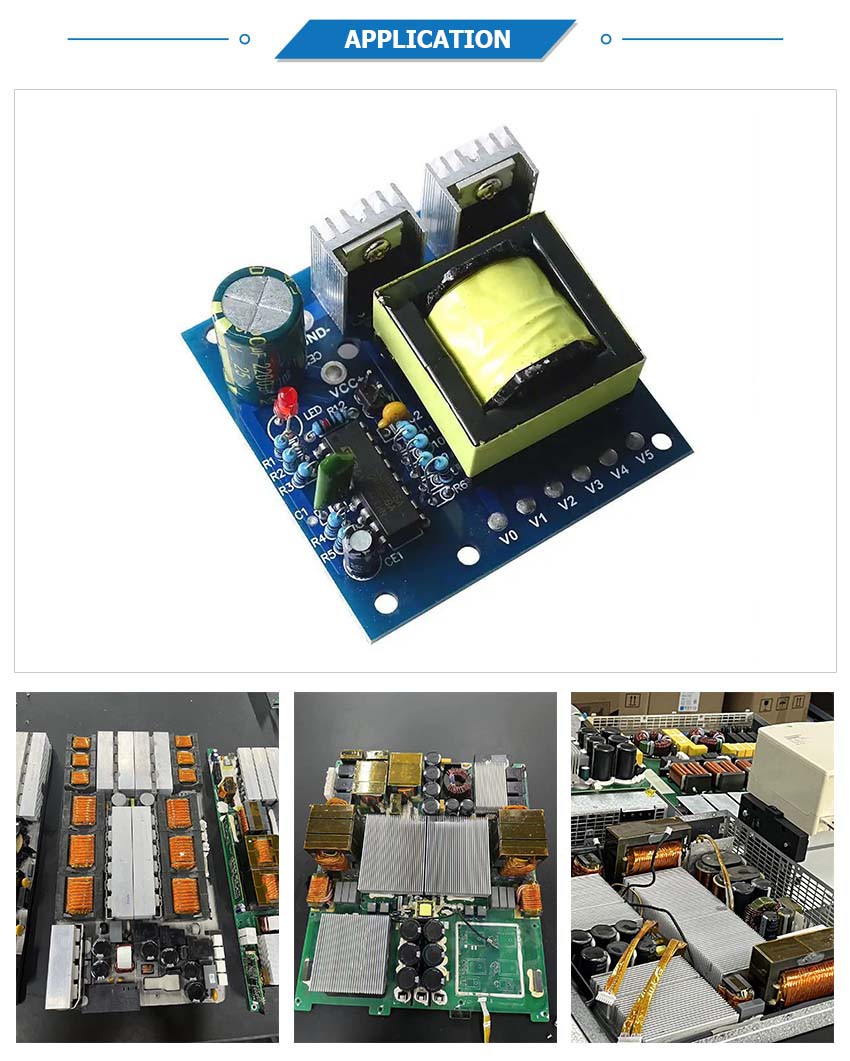

3. Strengthen heat dissipation measures

External heat dissipation means are indispensable. A heat sink can be installed on the surface of the core, and the large area of the heat sink can be used to increase the heat conduction area and quickly conduct the heat of the core to the surrounding environment. For some application scenarios with extremely high temperature requirements, air cooling or liquid cooling can also be used. Air cooling uses fans to force air flow to take away the heat of the core; liquid cooling uses coolant circulation to efficiently dissipate heat and ensure that the core is always in a suitable temperature range.

4. Control working parameters

Adjusting the working parameters of the core can reduce the impact of high temperature. Appropriately reduce the working current to reduce the heat generated by the thermal effect of the current. At the same time, according to the change of the magnetic permeability of the core in a high temperature environment, reasonably adjust the inductance value in the circuit to maintain stable circuit performance. For example, at high temperatures, the magnetic permeability of some cores decreases, and the inductance can be compensated by increasing the number of winding turns to ensure the normal operation of the circuit. If you want to learn more about the Inductor core, please visit www.hyper-elec.com!